Opening Hours : Monday to Friday - 09.00 am to 18.00 pm

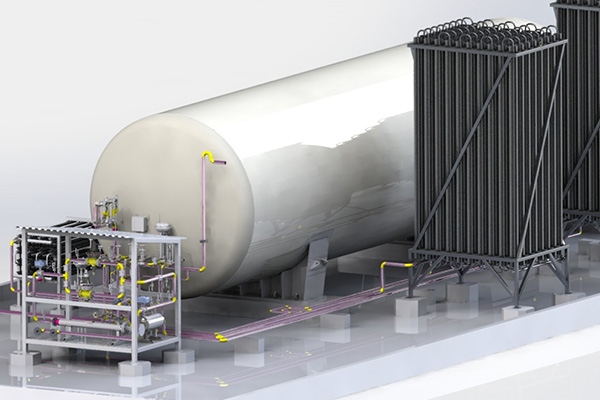

A facility that transforms liquefied natural gas (LNG) back into its gaseous state is called a regasification station.

In order for areas without direct pipeline connections to significant gas sources to have access to natural gas, regasification stations are essential to the worldwide LNG supply chain.

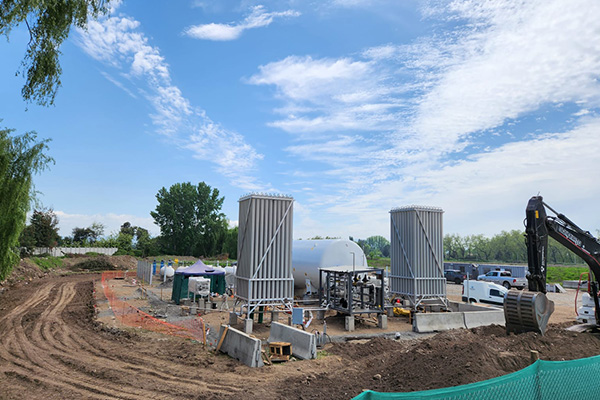

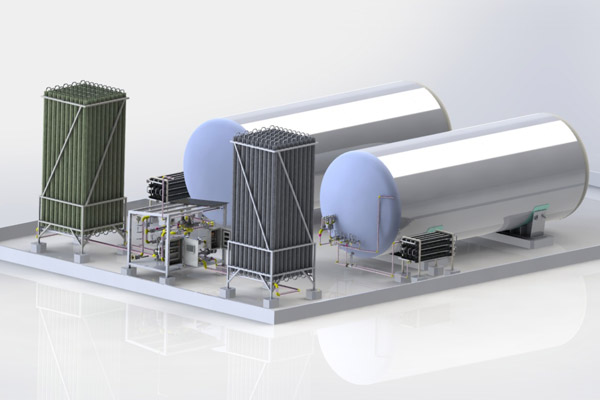

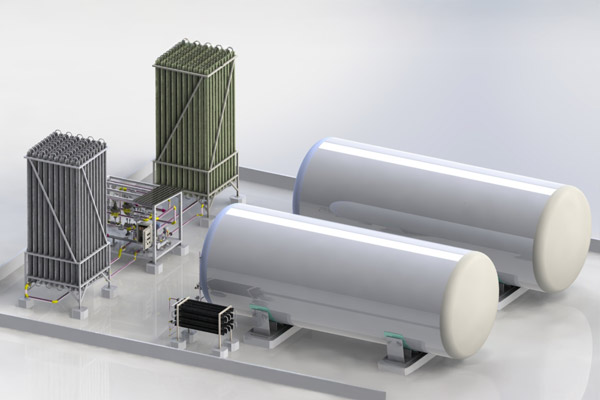

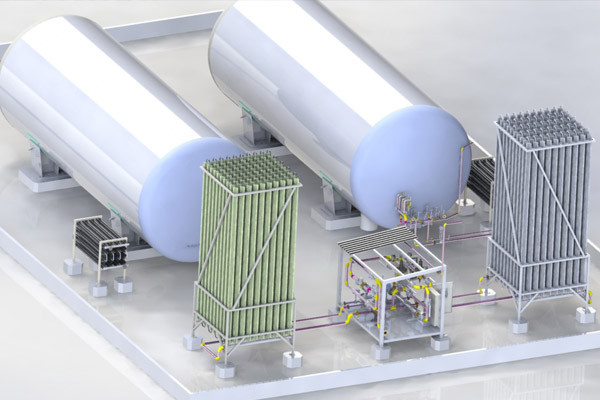

By designing, building, and maintaining gasification plants, Smart Industries enables businesses or communities without a gas pipeline network link to take use of natural gas's advantages. When pipelines are not practical, LNG is carried in a liquefied state (at extremely low temperatures) to facilitate long-distance movement.

In the past ten years, Smart Industrial has designed and commissioned more than fifty plants as subcontractors, meeting customer demands for storage capacity and flow demand while providing LNG facilities on a "Turnkey" basis.

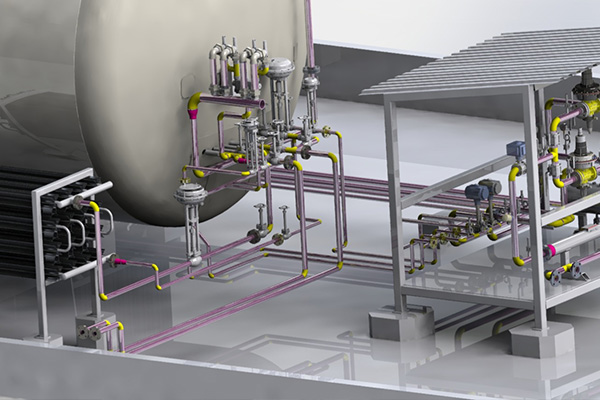

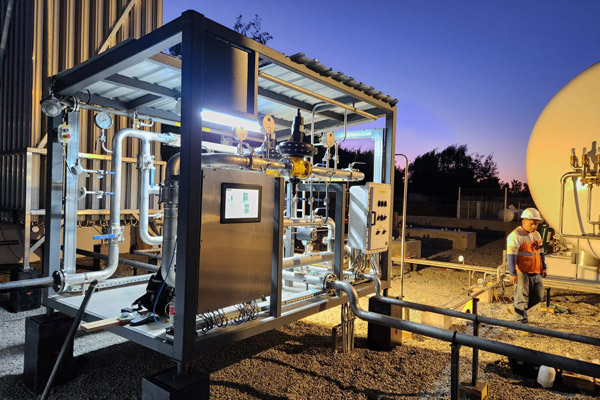

Smart Industries provides engineering, fabrication, and mechanical/electrical installation services on these projects.

The LNG is warmed up using heat exchangers or other techniques to convert it back into gas once it reaches the regasification station. After that, the local pipeline system receives this gas for distribution to residences, workplaces, and industries.

Specially designed plant installations may consist of:

- Electrical, water, steam, or ambient air can heat evaporators.

- Evaporators that use ambient air heating and gas heaters to maintain the lowest possible gas temperatures during cold weather pipelines that link components, including all devices to provide safe functioning.

- Containerised modules for plant control systems.

- Designs that adhere to local laws, EN-1473, EN-13645, ASME B31.3 or other standards.

The installations are certified in compliance with local requirements or have the proper CE marking in accordance with PED 2014/68/EU and ASME B31.3.

The LNG is warmed up using heat exchangers or other techniques to convert it back into gas once it reaches the regasification station. After that, the local pipeline system receives this gas for distribution to residences, workplaces, and industries.

- Regasification Capacity varies between 200 Nm³/Hr. to 50,000 Nm³/Hr.

- Design Temperature -196°C / +100°C (-320.8°F / 212°F)

- Plug and Play Design

- Easy Commissioning

- Easy to Use

- Long Service Life